Heat Treatment at Flexico Forging

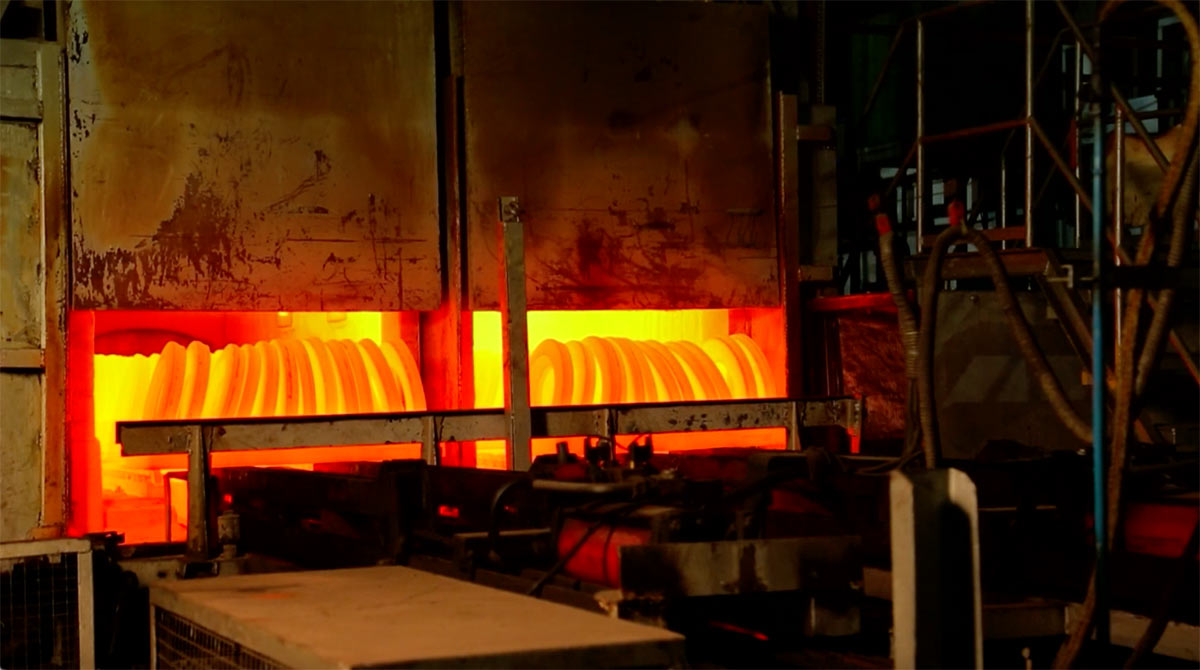

At Flexico Forging, we utilize advanced heat treatment technologies to ensure optimal strength, durability, and performance of our forged components. Our in-house heat treatment processes are PLC & SCADA-controlled, guaranteeing precision, consistency, and compliance with CQI-9 standards.

Our Heat Treatment Capabilities

- Normalizing

- Refines grain structure for improved machinability

- Enhances uniformity in mechanical properties

- Reduces internal stresses from forging

- Iso-Annealing

- Produces a uniform microstructure for better ductility

- Optimizes material for further processing

- Ensures consistent hardness and toughness

- Hardening & Tempering

- Increases hardness and wear resistance through quenching

- Tempering reduces brittleness while maintaining strength

- Ideal for high-stress components like gears and shafts

- Carburizing (Case Hardening)

- Enhances surface hardness while maintaining a tough core

- Improves wear and fatigue resistance.Why Choose Flexico for Heat Treatment?✔ State-of-the-art, PLC & SCADA-controlled furnaces

✔ Strict adherence to CQI-9 quality standards

✔ In-house processing for better quality control

✔ Customized treatment based on material & application

✔ Consistent and repeatable resultsApplicationsOur heat-treated forgings are used in:

- Automotive(gears, axles, crankshafts)

- Aerospace(landing gear, turbine components)

- Oil & Gas(valves, drill collars, flanges)

- Heavy Machinery(hydraulic components, bearings)

Quality Assurance

Every batch undergoes rigorous metallurgical testing, including:

- Hardness Testing (Rockwell, Brinell)

- Microstructure Analysis

- Impact & Tensile Testing

Need precision heat-treated forgings? Contact Flexico Forging today for superior quality and reliability!Used for automotive and industrial components