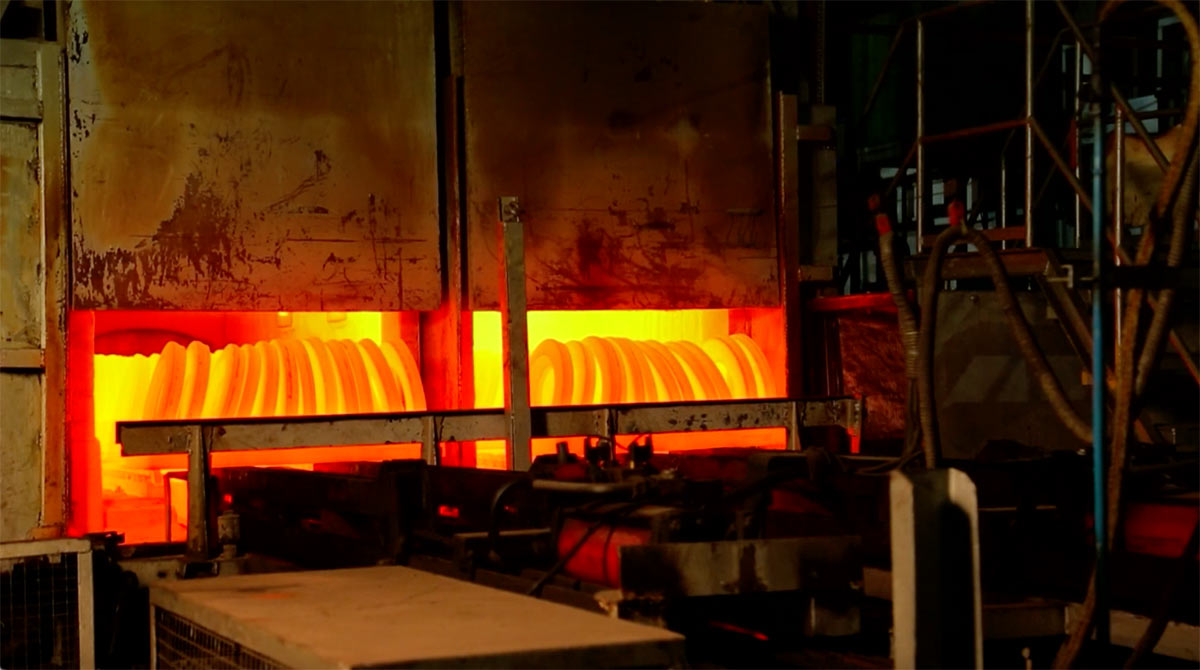

Heat Treatment

Heat Treatment at Flexico Forging At Flexico Forging, we utilize advanced heat treatment technologies to ensure optimal strength, durability, and performance of our forged components. Our in-house heat treatment processes are PLC & SCADA-controlled, guaranteeing precision, consistency, and compliance with CQI-9 standards. Our Heat Treatment Capabilities Normalizing Refines grain structure for improved machinability Enhances uniformity in mechanical properties Reduces internal stresses from […]

Open And Closed Die Forging

Open die forging is the process of deforming a piece of metal between multiple dies that do not completely enclose the material. The metal is altered as the dies “hammer” or “stamp” the material through a series of movements until the desired shape is achieved. Products formed through open forging often need secondary machining and […]

Die Manufacturing

In-house forging die manufacturing refers to the process of designing, machining, and maintaining forging dies within a Flexico’s own facility rather than outsourcing to external suppliers. This approach offers greater control over quality, lead times, and costs, making it ideal for high-volume or precision forging operations. Key Benefits of In-House Die Manufacturing Reduced Lead Times […]

Cutting Facility

Forging is a manufacturing process involving the shaping of a metal through hammering, pressing, or rolling. These compressive forces are delivered with a hammer or die. Forging is often categorized according to the temperature at which it is performed—cold, warm, or hot forging. We have an in house facility of cutting the blocks from raw […]

Shotblasting

Shot blasting is a resurfacing process used to remove irregularities from concrete, metal, and other industrial surfaces. While similar to the sand blasting process, shot blasting is different in both execution and effectiveness.Shotblasting is a much more aggressive abrasive technique than sandblasting. It’s usually used for larger and more difficult preparation objects that need a […]

Customised Forging

We can produce custom steel forgings weighing up to 12 kg and measuring 24 inches in length. Whether the part you need weighs just ounces or up to fifteen pounds, you can count on our team to produce resilient components for your needs. Additionally, we can produce custom components for a variety of industries, including […]

Machining

Our on site machining complex complete with CNC lathes, including live tooling as well as vertical/horizontal machining centers is your single source for precision machined parts. Forging and machining parts at one central location reduces both time to market for initial product launches and production lead times for ongoing orders. Using the same manufacturing data […]